- Technical advantages

- Service and guarantee

Technical advantages

Technical advantages

Concrete prefabricated house; The concrete prefabricated house adopts reinforced concrete structure. Through special equipment and molds, various prefabricated components are manufactured and processed in the factory according to our own patented technology and formula. The main types of components are: laminated beam, laminated column, laminated plate, PC outer wall panel, inner wall panel, balcony, air conditioning panel, stairs, etc., and then directly transported to the site for assembly, A building assembled on site through its own patented technology. With high degree of prefabrication, accurate size, fast construction speed, dry construction without pollution, low cost, energy conservation and environmental protection, the industrialized production of concrete housing has been truly realized. Compared with the traditional construction period, the construction site can save 80% wood, 60% water and 70% energy consumption. Its excellent performance determines the ultra-high performance-price ratio under comprehensive comparison. Concrete prefabricated houses can be widely used in civil buildings and public buildings, such as private villas, commercial houses, residential houses, industrial plants, office buildings, etc.

Concrete prefabricated houses are divided into two types:

1. Prefabricated concrete beam-column frame structure. 2. Fabricated concrete PC slab structure.

1. The prefabricated concrete beam column frame structure absorbs the essence of beam column structure, frame structure and hybrid structure, and is guided by the prefabricated structure. The factory standardizes the production of composite beams, composite columns and composite plates. Laminated floor+cast-in-place, floor and beam and column are integrally formed, and villa is built with bridge technology. It takes three steps to build villas, factories and residences. The first step is to produce all kinds of prefabricated parts in the factory, including composite beams, composite columns, composite plates, etc; In the second step, at the project site, the crane and other equipment will lift the beams and columns and use our patented technology to connect the nodes; The third step is to pour concrete together with the joint of beams and columns, so that the whole building can be connected as a whole, with high strength, good seismic resistance, corrosion prevention and fire prevention.

The prefabricated concrete frame beam-column structure is the frame beam-column bearing. Its structural characteristics are: 1. It is a frame structure. 2 The main structural members are beams and columns. 3. The connection of beams and columns is unique. 4. The beams and columns are prefabricated. 5. The installation of beams and columns is fabricated.

The connection mode of beam-column is the most critical part of prefabricated concrete frame beam-column structure, which is also the basic guarantee of structural safety. Through years of research and development and technical research, our company has developed a proprietary connection method, namely bolt positioning, reinforcement overall connection and grouting cement. This connection method is through the mutual engagement of embedded parts and accurate positioning; Convenient construction, fast installation and cost saving.

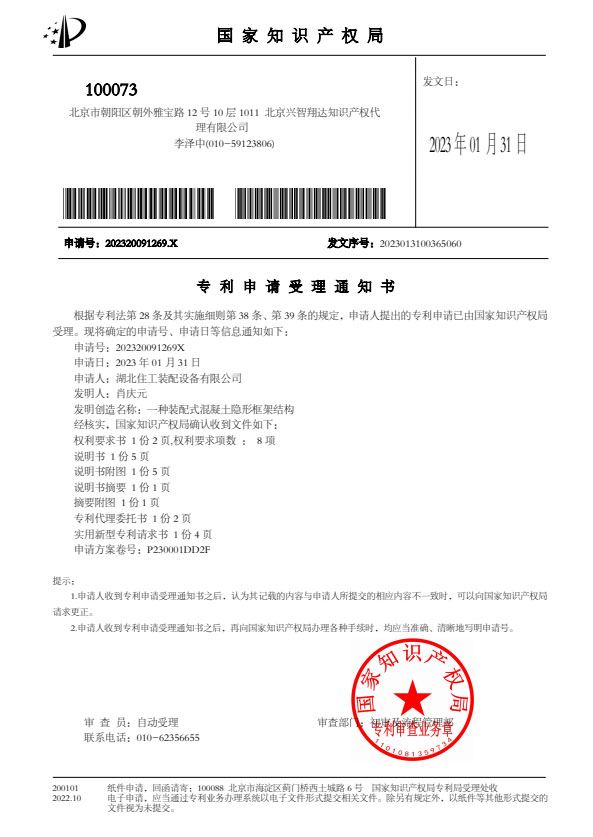

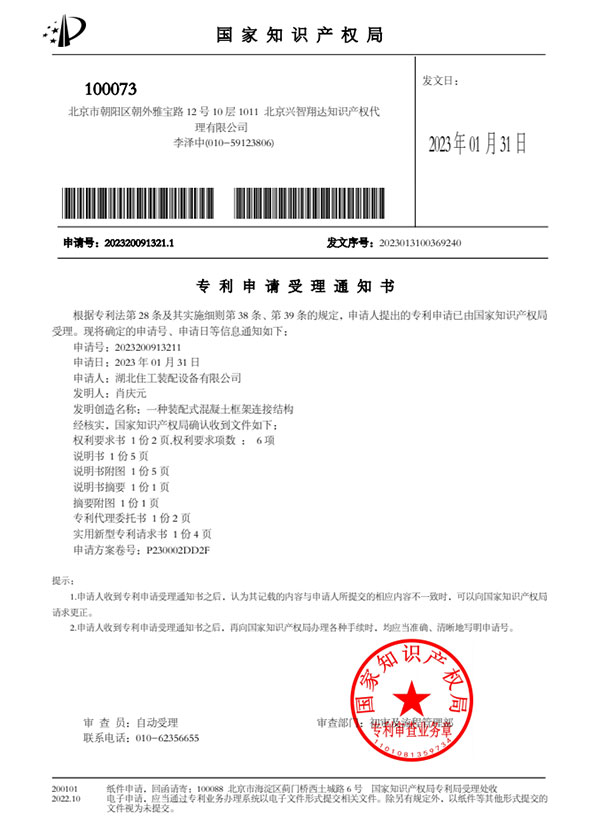

This connection mode has obvious advantages over similar products: 1. Low cost, saving 150 yuan per square meter of construction. 2. In this connection structure, the materials of the connecting members and the internal members of the composite beams and columns are the same, and the material's elasticity and stress resistance are the same, so as to avoid the later cracking of the joint after grouting. 3. The building speed is fast and labor is saved. The overall structure is solid and the structural design is simple. 4. Wall filling materials are easily purchased locally (aerated blocks, unburned bricks, etc.). 5. The house has a large built-in space. L-shaped, T-shaped, I-shaped, ten-shaped and other beam-column structures are adopted, and external corners will not appear around the wall. Our company adopts a patented technology independently developed - invisible beam-column structure.Patent No. 202320091269X (Fabricated concrete invisible frame structure)gentlePatent No. 2023200913211 (A prefabricated concrete frame connection structure)。

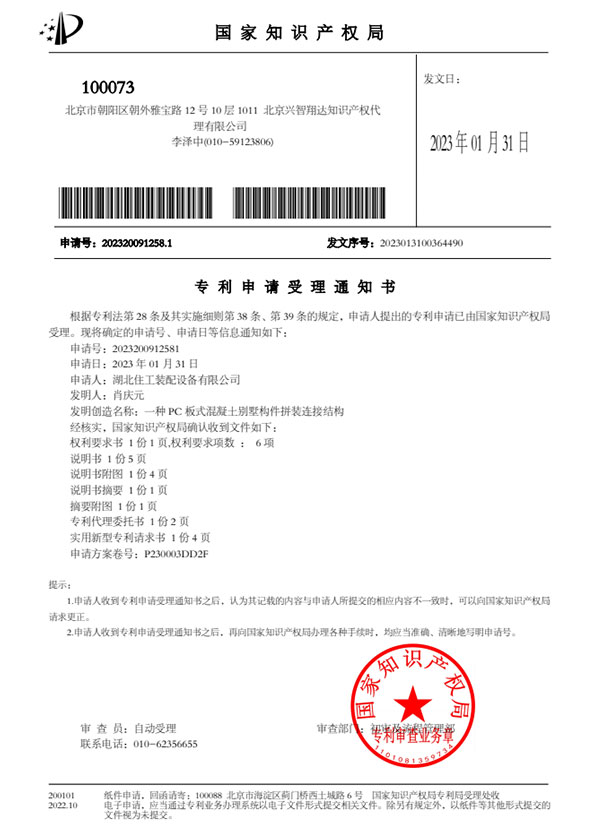

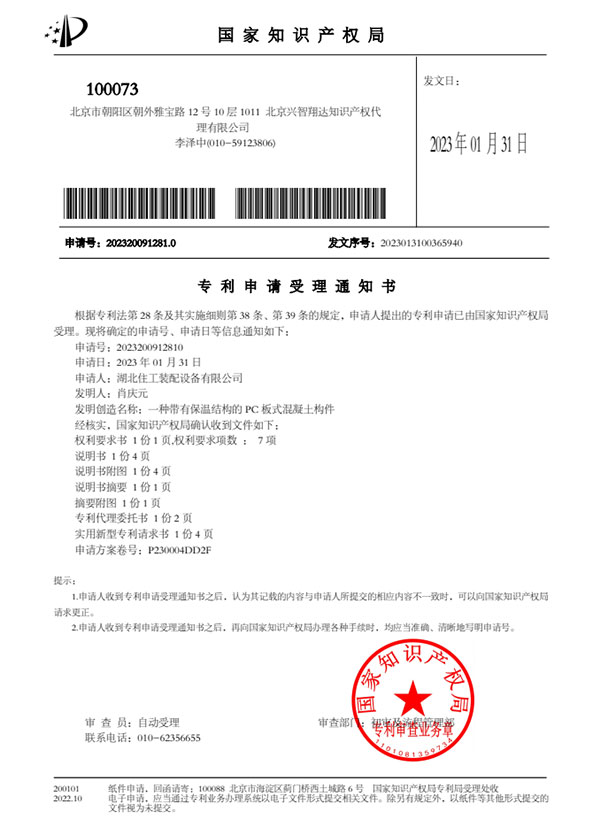

Patent certificate display

2. The prefabricated concrete PC panel structure is first standardized in the factory to produce PC wallboards, PC floors, stairs, balconies, air conditioning panels, etc., and then directly assembled on the site. The most critical is the connection mode between plates, which is also the basic guarantee of structural safety. Through years of research and development and technical research, our company has developed a connection mode with independent patented technology, namely high-strength sleeve connection.Patent No. 2023200912581 (A PC slab concrete villa component assembly connection structure)gentle Patent No. 2023200912810 (A PC slab concrete member with thermal insulation structure)。This connection mode is not only robust, but also greatly reduces the cost compared with similar products.

Patent certificate display